Introducing the Olympus FSE Parts Inventory Application

Overview of the Olympus FSE Parts Inventory Application

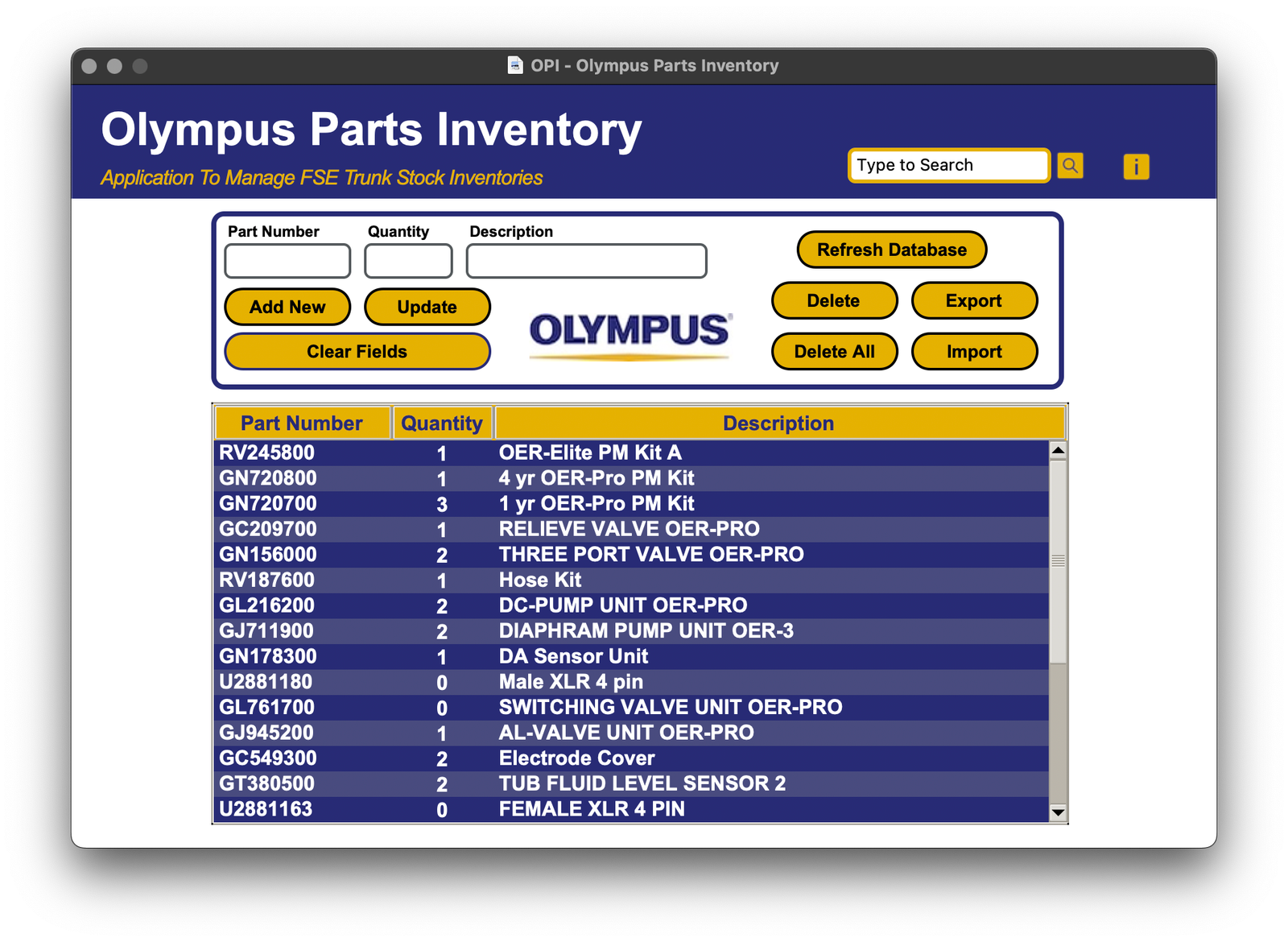

The Olympus FSE Parts Inventory Application is designed to streamline the management of field service engineer (FSE) parts inventory. This innovative application serves as a crucial tool for organizations that require accurate tracking and efficient organization of their inventory. Its primary purpose is to facilitate the monitoring of parts, ensuring that FSEs have access to the necessary components for timely and effective service delivery.

One of the key features of the Olympus FSE Parts Inventory Application is its user-friendly interface, which allows users to quickly navigate through the various functionalities. The application provides real-time updates on inventory levels, enabling FSEs to determine the availability of parts at any given time. This can significantly reduce downtime during service calls, enhancing overall operational efficiency. Additionally, the application includes the ability to export the database to excel spreadsheet for both reports and backup. Utilizing the import feature, the database can be updated or restored.

Moreover, the application is tailored for its target audience, which includes field service teams. By addressing the specialized requirements of these groups, the Olympus FSE Parts Inventory Application helps to alleviate common inventory challenges. It ensures that users can maintain optimal stock levels, thus preventing both overstock situations and shortages that could hinder service operations.

The convenience offered by this inventory management application is not limited to tracking parts; it also aids businesses in achieving a more organized and efficient approach to parts management, ultimately contributing to improved service delivery and customer satisfaction.

Key Features and Functionalities

The Olympus FSE Parts Inventory Application is designed with a comprehensive range of functionalities that streamline the process of managing parts inventories. One of the significant features is the ability to add new parts to the database effortlessly. Users can navigate to the ‘Add New’ section, where they are presented with an intuitive form. By simply entering the relevant details such as part number, description, and quantity, users can ensure their database remains up-to-date and accurately reflects the inventory status.

Another critical functionality of the application is the search capability, allowing users to locate parts quickly. Utilizing either part numbers or descriptions, the search functionality provides results in real time, giving users instant access to the information they need. This feature is particularly advantageous in environments where time is of the essence, as it minimizes downtime by providing swift access to inventory data.

Furthermore, the Olympus FSE Parts Inventory Application supports both importing and exporting data seamlessly. Users can export their part lists in excel spreadsheet format, which is invaluable for generating reports or backing up information. The import functionality is equally efficient; it allows users to upload bulk parts data using standardized excel template. This feature minimizes manual entry, thereby reducing the potential for errors and saving valuable time.

The user-friendly interface of the application is a hallmark of its design. It ensures that both novice and experienced users can navigate the system without undue difficulty. The streamlined processes for adding, searching, updating, and managing parts enhance the overall efficiency of the inventory management process, providing a reliable solution for maintaining accurate records of parts inventories.

Technical Insights: Building the Application with Python

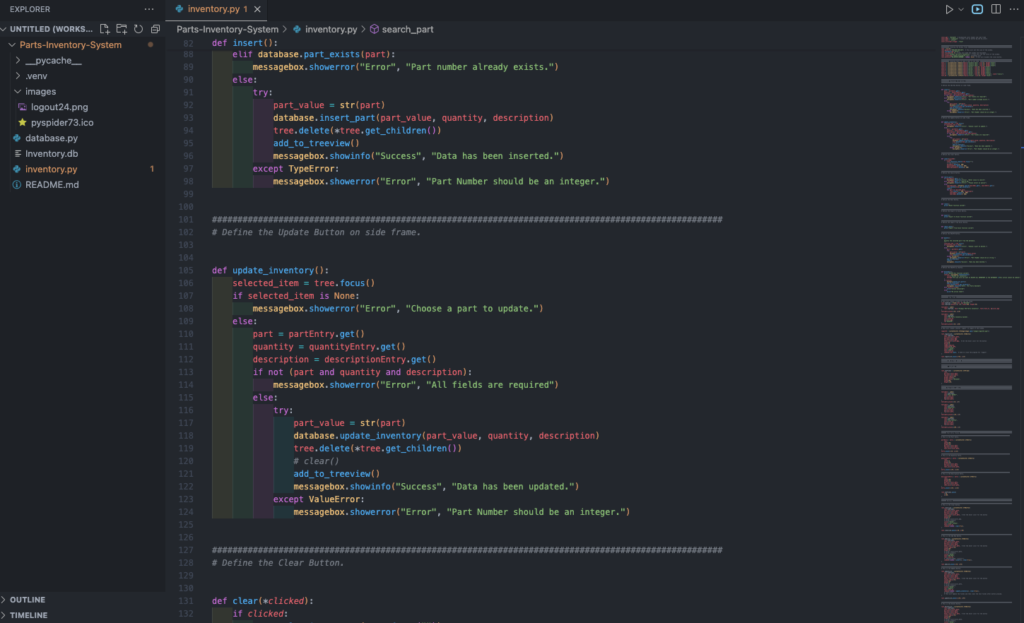

The Olympus FSE Parts Inventory Application utilizes Python as its core programming language. Python’s versatility and extensive libraries, such as Tkinter, CustomTkinter, Pillow (PIL), and TreeView make it an ideal choice for building robust applications, particularly in the realm of inventory tracking where real-time data processing is paramount.

The development of the Olympus FSE Parts Inventory Application utilizes several key libraries and frameworks. Notably, SQLite is integrated for database interactions, facilitating seamless communication between the application and the underlying database. This combination enhances the application’s ability to manage parts inventory efficiently, allowing for smooth data retrieval and storage.

The application architecture follows a model-view-controller (MVC) pattern, which supports organized code structure and ease of maintenance. Each component, from data models to user interface, is easily modifiable, providing room for future enhancements.

In conclusion, the technical design and implementation of the Olympus FSE Parts Inventory Application exemplify the advantages of using Python in application development. By harnessing its libraries, frameworks, and architectural patterns, the application not only meets current inventory management needs but also lays the groundwork for future advancements.

Utilizing the Application: A Practical Guide

The Olympus FSE Parts Inventory Application serves as a powerful tool for managing inventory in a seamless and efficient manner. To utilize this application effectively, it’s essential to familiarize oneself with its user interface. Users are greeted with an intuitive dashboard that presents various functionalities at a glance. To enhance your experience, take a moment to explore each section.

One of the key applications of the Olympus FSE Parts Inventory Application is streamlining the inventory management process. For instance, technicians can quickly check the availability of parts needed for repairs, reducing downtime and improving operational efficiency. By utilizing the application’s search feature, users can locate specific parts using part numbers or description, which enhances efficiency considerably.

For optimal results, it is important to adopt best practices while using the application. Regular updates and maintenance of the inventory records are crucial to ensure data accuracy. Implementing a periodic review process to confirm that all parts are correctly categorized and accurately counted will help avoid discrepancies. By leveraging these tools and strategies, users can significantly enhance their inventory management process and ensure efficient operation within their organization.